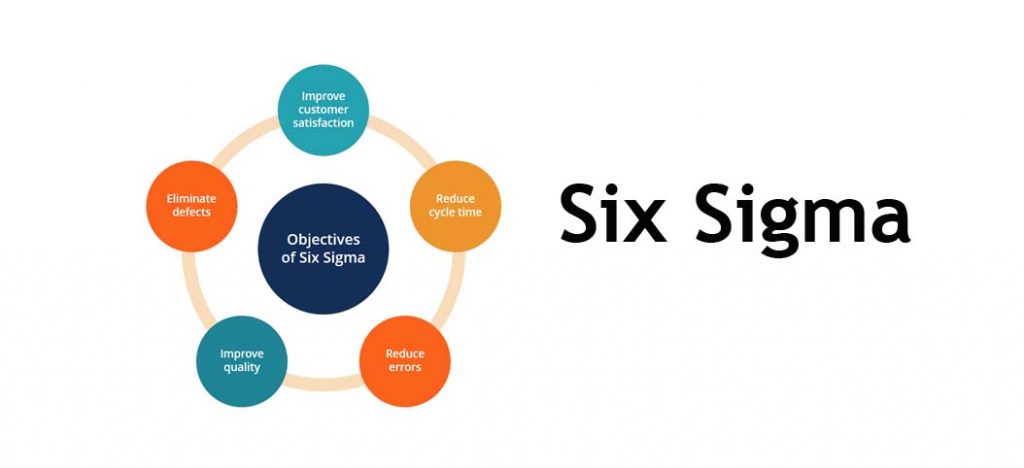

The word Six Sigma might sound strange to a lot of ears. For hundreds of years, the industrial world has been seeking greater performance and better output quality. And Six Sigma is one of the solutions in the last 35 years.

Six Sigma, which is referred to as a management philosophy, focuses on improving business statistics. It supports qualitative performance metrics against qualitative markers.

The Six Sigma practitioners are those organizational people that use statistics, financial analysis, and project management to reinforce their business processes.

Six Sigma

It has grown to explain various ideas, mostly within the business sphere and sometimes confusing. First, it is a statistical benchmark.

Any strategic business plan that produces under 3.4 defects per 1 million chances been considered to be efficient. Anything created aside from customer satisfaction could be a defect.

Secondly, it is a training and certification program that teaches Six Sigma’s fundamental principles. Interested aspirants can be granted the Six Sigma certification belt levels from white to black belt.

Finally, it is also a strategy that supports the concept of evaluating and optimizing all business processes. Six Sigma statistics explain how the method is accomplished quantitatively.

Six Sigma Lean

A measurement approach aimed toward enhancing procedures and minimizing variance through the implementation of six Sigma improvement projects is Six Sigma Methodology’s fundamental goal. This is done by two sub-methods of Six Sigma: DMAIC and DMADV.

What is Six Sigma

Six Sigma is a technique that permits business processes by statistical analysis. This is a highly disciplined and data-driven methodology that ensures defect elimination in any company or organizational phase.

Organizational procedures must retain a maximum of 3.4 per million (99.99966%) opportunities to attain it.

Motorola developed Six Sigma in 1986 and is basically collecting tools and techniques to enhance processes. This is also a top method to increase the productivity and efficiency of business processes.

It offers tools and techniques that reduce variance, eliminate defects, help identify root causes of failure. And enable organizations to deliver better products and services for the customer.

Importance of Six Sigma

Since its adoption as a company strategy by Jack Welch at General Electric in 1995, it has come a long way. This is also been widely implemented in a wide selection of all industrial sectors.

Implementation of this strategy is important because it benefits organizations in several ways. This strategy has grown in recent years into a more general corporate management philosophy centered on customer needs.

Six Sigma Principles

You can note a minor variance within the Six Sigma principles, based on where you look. These are the ideas that guide the methodology generally.

- Constant efforts are essential for the expansion of the company to become reliable and consistent process outcomes.

- The business processes and manufacturing having characteristics are often defined, measured, analyzed, improved, and controlled.

- Sustainable quality improvement needs the entire company’s dedication, and perhaps particularly of senior and mid-level management.

- All processes are often precisely described, evaluated, and improved: You will be able to monitor outputs by controlling the inputs.

- It is essential for formative evaluation. Stop what you are doing and think about what has gone wrong or right.

- Variance elimination saves money and avoids defects.

And there you get it.

Six Sigma Certification

This represents a verification of an individual’s command for a popularly known professional skills development process.

Six Sigma training certifications are awarded bit by bit accessing a method just like a belt classification used in karate training.

Though there’s no formal body of training or certification, many training organizations offer Lean Six Sigma certification. Various schools and businesses will deliver their variations.

Some educational and consulting organizations are joining together to own a version they support. It is done on-site, self-paced, classroom, online, or from a combination of all. Certificates are issued after completing a written exam, which may be taken online or on paper.

Besides being a prerequisite for workplaces, the credential is present on a resume and may earn the maximum amount payable as an MBA.

These strategy projects will provide benefits, including improved corporate performance, customer loyalty, cost savings, higher income, and more.

Certified Six Sigma Black Belt (CSSBB):

The Six Sigma Black Belt is a known specialist who can explain the philosophies and ideas of the strategy, including systems and resources.

A Black Belt should show team leadership, recognize team dynamics, and choose team members’ roles and duties. Following its principles, Black Belt understands all aspects of the DMAIC models thoroughly.

They possess a fundamental knowledge of lean organizational principles, recognize components and practices that aren’t value-added, and may use those tools.

Certified Six Sigma Green Belt (CSSGB):

The CSSGB works to assist the Six Sigma Black Belt or, under the guidance of it, analyses and addresses quality issues.

Certified Six Sigma Yellow Belt (CSSYB):

The CSSYB targets those that have a short position, an interest, or want to build fundamental knowledge in Six Sigma’s world.

The yellow belt is for entry-level employees who want to strengthen their world or champions who require an overview of DMAIC and Six Sigma.